Starke Electric Chain Hoist

- 1⁄2 to 5 Ton

- Single Speed Lift

- Up to 26 FPM (More details below).

- 20′ Lift

- Pendant included. It will always be 3′ shorter than the length of chain.

Work Anywhere

The Starke Electric Chain Hoist is your only solution for heavy duty lifting. You get to choose your lifting capacities from 1/2 Ton – 5 Ton. You’ll be able to get the job done no matter if you’re working on high production assembly lines or in a hobby garage.

Built to Last

This hoist is built only with quality materials and contains the latest technology. The Starke Electric Chain Hoist will last a lifetime.

Expertly Designed

Designed with your needs in mind, you’ll be able to add this hoist anywhere. It can attach to an existing trolley through the hoist’s rigid hook attachment. For even better performance, pair it with a Starke Low Headroom Plain Trolley or Starke VS Motorized Trolley.

Go Wireless

All Starke Electric Chain Hoists are compatible with Starke Echo Radio Remote Control Systems. If purchased together, your electric chain hoist will be wireless and ready to use right out of the box. The benefits of using a radio control system with your hoist is that you won’t have to use a pendant. You’ll be able to operate your hoist wirelessly from a distance up to 300 feet.

Features

- Lift Speeds

- 1/2 Ton : 26 FPM

- 1 Ton: 26 FPM

- 2 Ton: 26 FPM

- 3 Ton: 21 FPM

- 5 Ton: 11 FPM

- Metric Rated Capacity

- Duty Class: H4

- Quick-Connect Power & Pendant Controls

- Durable Canvas Chain Container

- Japanese FEC Grade #80 Lifting Chain

- Schneider Electric Control Contactor

- NSK Main Bearings

- Paddle Type Limit Switch for Up/Down Travel

- 360° Swivel Hook with Safety Latch

For more information about Starke, visit starkeamerica.com.

Starke Hoist Motor Horsepower & Amp Information

| Capacity | Horsepower | Amps |

| 1/2 Ton | 1 | 1.9 |

| 1 Ton | 2 | 6.5 |

| 2 Ton | 3 | 6.5 |

| 3 Ton | 3 | 6.5 |

| 5 Ton | 3 | 6.5 |

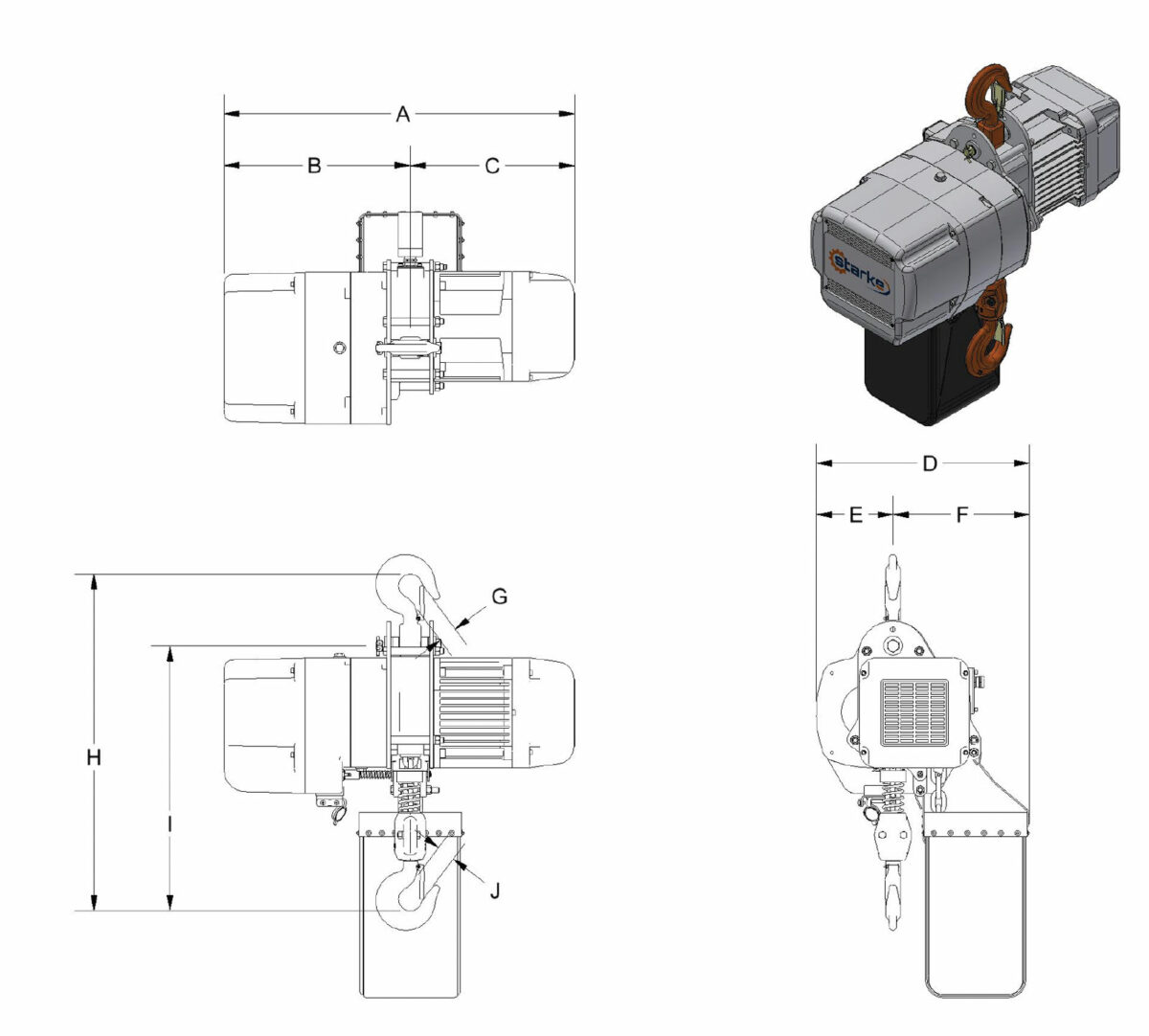

Starke STK Series Dimensions

| Dimensions | Headroom Dimensions | |||||||||

| SKU | A | B | C | D | E | F | G | J | (I) Lug Pin | (H) Standard |

| STK0526 | 22 3/8" | 11 7/8" | 10 1/2" | 12 1/2" | 4 3/8" | 8 1/8" | 1 1/16" | 1 1/16" | 17 13/16" | 21 15/16" |

| STK1026 | 24 5/8" | 12 13/16" | 11 13/16" | 12 1/8" | 4 15/16" | 7 3/16" | 1 1/4" | 1 1/4" | 18 5/8" | 23 1/4" |

| STK2026 | 28 13/16" | 15 5/16" | 13 1/2" | 17 9/16" | 6 5/16" | 11 1/4" | 1 1/2" | 1 1/2" | 21 13/16" | 27 11/16" |

| STK3021 | 28 5/16" | 15 7/16" | 13 1/2" | 16 5/16" | 6 3/8" | 9 15/16" | 1 3/4" | 1 3/4" | 27 5/8" | 31 13/16" |

| STK5011 | 28 5/16" | 15 9/16" | 13 3/8" | 16 5/16" | 4 1/16" | 12 1/4" | 1 7/8" | 1 7/8" | 27" | 36 1/2" |

Kevin (verified owner) –

Good Hoist at a fair price

J Armfield –

For what my client needed in terms of lifting capacity and duty cycle, this hoist works quite well. After more than a month of use, the two units purchased (one as part of a Hyperlite crane system) continue to work without issue. PWI was great about installation and making sure the units were load tested prior to “handing over the keys”.